Products

Customized Machinery

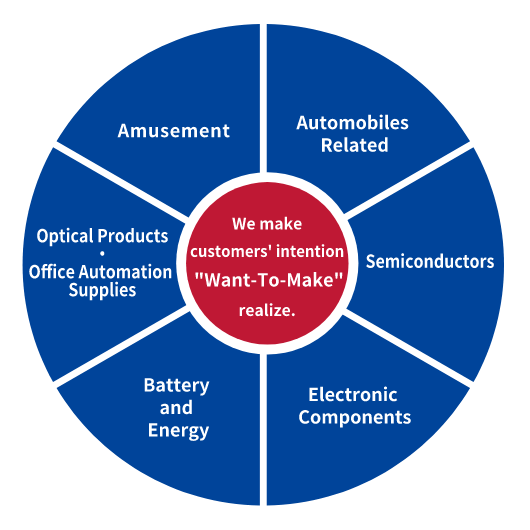

We make customers’ intention “Want-To-Make” realize.

We propose customized machinery in which customers’ technical requirements are thoroughly incorporated, through our exclusive technical know-how and experiences to have been acquired and accumulated so far and our engineering team’s aggressive commitments.

In addition, we are pleased to help customers with an initial planning of machine configuration, designs, built-up, installation at customers’ sites and after-sales service.

Production Flow

Meeting

We generate an optimized initial planning of machine cofiguration based on customers’ technical requirements.

We share and discuss our generated initial planning of machine configuration with customers and acquire customers’ latent technical requirements for a purpose to propose quotes.

Production

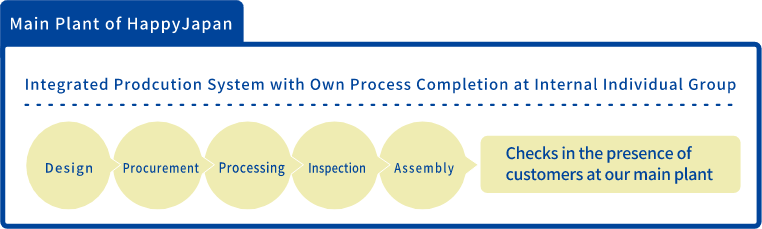

We offer machinery with high quality in a timely manner through our integrated production system as our superiority.

Final Running Check and Final Acceptance

Ordered machines will be delivered to customers’ designated locations. Final acceptance to officially buy ordered machines off will be conducted immediately after customers’ final approvals of the installed machines at customers’ sites.

After-Sales Service

We will offer after-sales service for a purpose to enable customers to keep using our designed machines in a satisfactory level after final acceptance.

Profile of Our Designed Machinery

Automobiles Related

- Throttle Assembly Machine

- Electric Fuel Pumps Assembly Line

- Injector Assembly Machine

- Injection-Related Winding and Assembly Line

- Alternator-Related Starter Motor Assembly Machine

- Alternator-Related Rotor Motor Assembly Machine

- Motor-Coil Forming Machine

- Motor-Coil Insertion Machine

- Motor-Coil Welding Machine

- Insulator Insertion Machine

- Lens Assembly Machine

Semicondctors

- Plural High-Speed Spattering Machine

- Die Bonding Machine

- Visual Inspection Machine

- Temp. Characteristic Inspection Machine

- Insert Remover

- Reverse Inserter

Electric Components

- IC Chip Placement Machine

- LCD Assembly Machine

- TFT Overlaying Machine

- PDP Overlaying Machine

- DVD Manufacturing Line

- HDD Automatic Assembly Line

- Board Dividing/Feeding Machine

- Speaker Assembly Line

Battery, Energy

- Solar Cell Manufacturing Line

- Square-Shape Battery Assembly Line

- Polymer Battery Manufacturing Line

- Lithium Battery Automatic Assembly Line

- Lithium Battery Seam Welding Machine

- Lithium Battery Injection Port Welding Machine

- Lithium Battery Tab Welding Machine

- Lithium Battery Injection Machine

- Sealing Machine

- Terminal Welding Machine

Optical Products, Office Automation Supplies

- Camera Assembly Machine

- Film Exposure Apparatus

- Glass Forming Machine

- Screw Tightening Machine

- Leak Test Machine

- Ink Tank Rinsing /Drying Machine

Amusement

- Fully Automated Nailing Machine

- Fully Automated Nailing Inspection Machine

- Fully Automated Pinwheel Installation Machine

Main Processing Machines

Vertical Machining Center

| 5-axis Machining Center | DMC125FD (DMG MORI) |

|---|---|

| Vertical Machining Center | DureVerticel 5060 (DMG MORI) NVX5080Ⅱ (DMG MORI) NVX5080 (DMG MORI) NVX5080 (DMG MORI) CMX600 (DMG MORI) CMX600 (DMG MORI) VK65 (Hitachi Seiki) VK55 (Hitachi Seiki) VM40 (Hitachi Seiki) VA40 (Hitachi Seiki) V56 (Makino Milling Machine) FNC74-A20 (Makino Milling Machine) FDNC128-A20 (Makino Milling Machine) NVD1500 (MORI) NV4000 (MORI) NVD4000 (MORI) NVD4000 (MORI) |

Horizontal Machining Center

| CNC Horizontal Jig Boring Machine | DIXI350(DIXI) |

|---|---|

| Horizontal Machining Center | NHX6300 (DMG MORI) NHX6300 (DMG MORI) NHX4000 (DMG MORI) HG630 (Hitachi Seiki) HC500 (Hitachi Seiki) HC500 (Hitachi Seiki) MCB1513 (Makino Milling Machine) MCB1513 (Makino Milling Machine) A55ε (Makino Milling Machine) A55 (Makino Milling Machine) MCD1816 (Makino Milling Machine) a81M (Makino Milling Machine) a81M (Makino Milling Machine) |

Double-Column Machining Centers

| Double-Column Machining Centers | MCV-16A (OKUMA) |

|---|---|

| 5-Face Machining | VE26-40 (Hitachi Seiki) |

| Drill Center | FMC-15VP (Fuji Seiki) |

NC Drilling Machine

| NC Drilling Machine | DRILLMate-MODEL T (FANUC) DRILLMate-MODEL T (FANUC) DRILLMate-MODEL T (FANUC) DRILLMate-MODEL T (FANUC) DRILLMate-MODEL 10 (FANUC) |

|---|

NC Lathe

| NC Lathe | 3NE-300 (Hitachi Seiki) 3NE-300 (Hitachi Seiki) CL1500 (MORI) NL2500/1250 (MORI) NL3000/1250 (MORI) |

|---|

NC Milling Machine

| Vertical Milling Machine | BNⅡ85-A6 (Makino Milling Machine) FDX-106 (Makino Milling Machine) |

|---|---|

| Horizontal Milling Machine | PNC-MSP (Hiraoka Kogyo) |

Drilling Machine

| Radial Drilling Machine | RE2-1300A (OOYA) RE2-1300A (OOYA) HOR-D2000 (Ogawa Iro Works) |

|---|---|

| Drilling Machine | ATD-360 (ASHINA) YGD-900CT (Yoshida Tekkoujo) YGD-900CT (Yoshida Tekkoujo) YUD-540 (Yoshida Tekkoujo) |

Lathe

| Lathe | HB-575 (SHOUN MACHINE TOOL) KG-6670A (HAMATU) KG-6670A (HAMATU) |

|---|

Milling Machine

| Vertical Milling Machine | MS-V (Hitachi Seiki) 2ML-V (Hitachi Seiki) YMV-1000 (YAMAGUCHI) RTM-2 (RIKEN SEIKO) |

|---|---|

| Horizontal Milling Machine | 3ML-P (Hitachi Seiki) MS-P (Hitachi Seiki) |

Large General-purpose Machine

| Horizontal Boring Machine | BT-10B (TOSHIBA MACHINE) |

|---|---|

| Plano Miller | 12MJ 40 (Hitachi Seiki) |

| Jig Boring Machine | J 6B (MITSUI SEIKI) |

Wire-Cut

| NC Electric Spark Machine | AW-453 (Sodick) |

|---|---|

| Wire-Cut Electric Spark Machine | EU64 (Makino Milling Machine) |

| Wire-Cut Electric Discharge Machine | SP64 (Makino Milling Machine) |

Grinding Machine

| Super Precision Surface Grinding Machine | SGC156BL2-PNC (NAGASE INTEGREX) |

|---|---|

| Profile Grinding Machine | JF520-CNC-B (Carl Jung) |

| CNC Cylindrical Grinding Machine | UR175×1000 (Kellenberger) |

| Precision Cylindrical Grinding Machine | GP15-100 (TOYODA) |

| Surface Grinding Machine | PSG-5 (Okamoto) |

| Internal Grinding Machine | YIG-15 (Yamada Koki) |

Thin Sheet Metal Equipment

| YAG Laser Machine | TruMatic3000 (Trumpf) |

|---|---|

| YAG Laser Welder | TruLaser Handy (Trumpf) |

| Press Brake | TruBend5085SX (Trumpf) TruBend5085X (Trumpf) |

| Bending Roll | BU-S2000 (isel) |

| Welding Machines | WB-M350L (DAIHEN) |

| AC Spot Welding Machine | SLAJ50-610 (DAIHEN) |

Measuring Equipment

| Three-Dimensionsal Measuring Machine | PMM12106 (Leitz) |

|---|---|

| Horizontal Length Measuring Machine | TELMN (TRIMOS SYLVAC METROLOGY) |

| Vertical Length Measuring Machine | MICRO-HITE600 (TESA) |

| Microscope | VHX5000 (KEYENCE) |

| Outside Micrometer | 0.001mm~175mm (Mitutoyo) |

| Inside Micrometer | 5mm~75mm (Mitutoyo) |

| Blade Micrometer | 0.01mm~50mm (Mitutoyo) |

| Tooth Thickness Micrometer | 0.001mm~100mm (Mitutoyo) |

| Holtest | φ6~φ100 (Mitutoyo) |

| Calipers | 0.01mm~200mm (Mitutoyo) |

| Dial Indicator | 0.01mm~10mm (Mitutoyo) |

| Height Gage | 0~300mm (Mitutoyo) |

| Dial Test Indicator | 0.01mm~0.5mm (Mitutoyo) 0.01mm~0.5mm (TESA) |

| Ring Indicator | φ4~φ12 (MDK) |

| Plain Gauge | φ3~φ50 (Alps) |

| Test Bar | φ6~φ100 (TSI) |

Skill Certified Engineers (Person)

| Machining Techniques (Special Grade) | 10 |

|---|---|

| Machining Techniques (Grade 1, Grade 2) | 62 |

| Machine Maintenance, Machine Inspection (Special Grade) | 2 |

| Machine Maintenance, Machine Inspection (Grade 1, Grade 2) | 8 |

| Finishing (Outstanding Special Grade) | 4 |

| Finishing (Grade 1, Grade 2) | 19 |